OUR PROCESS

OUR PROCESS

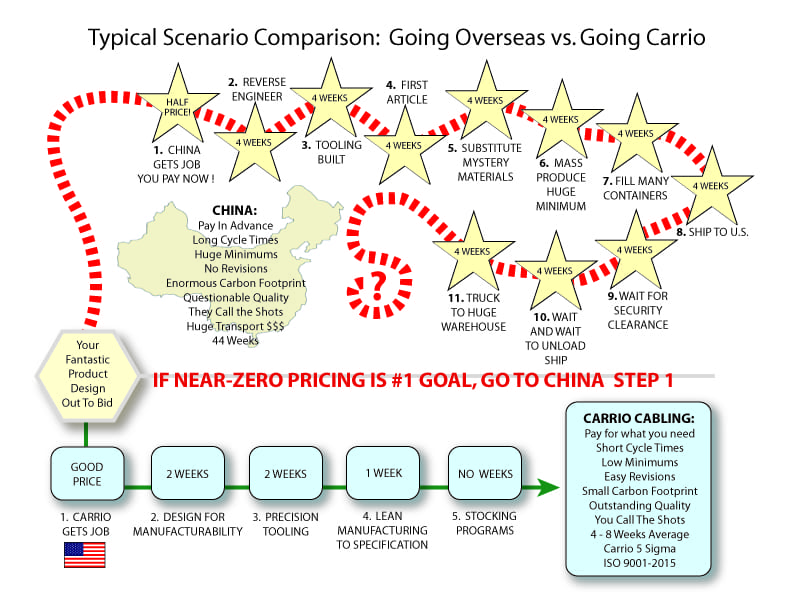

Whatever you can conceive, Carrio Cabling can Sketch, Design, Prototype, Tool, Manufacture, Test, and Ship. Every Carrio product is made in the United States, creating jobs by providing American cable molding, design, and manufacturing.

1. Sketch

Every cable begins with an idea – a solution to a problem. Carrio Cabling will take your cable from sketch to delivery.

2. Design

Carrio Cabling’s in-house engineering design team looks at your idea in its present form, which could be anything from a sketch on a lunch napkin to a full schematic.

3. Prototype

We take it to the next step with Carrio’s stereolithography (SLA) or low-force SLA equipment and make a rapid prototype of the cable molding.

4. Tool

Carrio Cabling has tool and die equipment for injection mold tooling on site. We tool the cable molding in house, which shortens lead times and means you get your final product faster.

5. Manufacture

After we have the right design and prototype, it is time to manufacture to your specifications, following Carrio Cabling’s disciplined practices for excellence in cable assembly manufacturing.

6. Test

We test and we test. Did we mention we test? Product integrity is the foundation of Carrio Cabling.

7. Ship

Carrio’s commitment is to always timely ship your products so they are delivered when you need them.