LASER TAG COIL CORD

LASER TAG COIL CORD

Carrio Cabling saves a customer warranty replacement costs by manufacturing a superior custom coil cord that can take a beating and still hold its shape. Carrio Cabling’s ability to manufacture low quantities also saves the customer money by allowing the customer to maintain low inventory levels.

Situation:

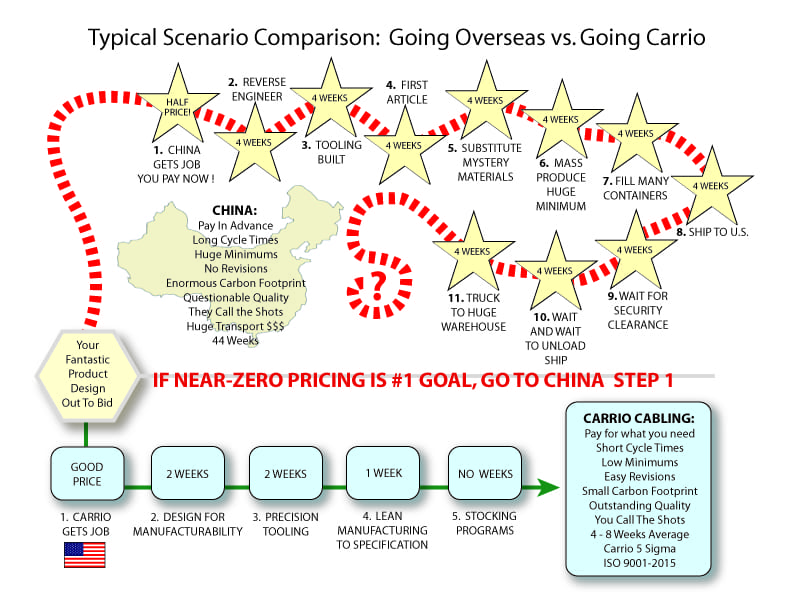

A company has the contract to provide and service laser tag game equipment to arenas across the United States. The coil cord that connects the laser gun to the sensitized body armor becomes hyperextended and will not return to the correct shape. In addition, the ends pull off easily under the rugged use of action-packed players (usually 10-year-old boys). Warranty costs are a huge problem. A company representative says that although the Chinese price is low, he is required to purchase huge minimum quantities (far more than he needs) and he must pay in advance. To make matters worse, the coil cords received from overseas are made of inferior materials that do not match the specs or drawings.

Solution:

Solution:

A company representative called Carrio to see what we could do. We told him we could not begin to compete with the Chinese price because it was less than our cost of materials if we built the cords according to his drawings and specs. He asked us to move ahead and offer ideas to solve his problems.

The Carrio Team re-engineered the coil cord design so that the cord would perform correctly and withstand extreme abuse and built the cords in the smaller quantities that the customer needed. Although our per-cord price was higher than the overseas price given the smaller quantities really needed, the customer saved money because our coil cord was much stronger. Carrio’s redesign has translated into fewer cords used each year and significant reductions in warranty costs.

Carrio Cabling designs it right, builds it strong, and saves you money. What more could you want?

Made in the USA.

Carrio Cabling: Give Us the Tough Stuff™