We All Love To Wait…. Don’t We?

What’s Up With Long Lead Times?

Several months ago, a customer said something to me that was another example of the utter fascination people have with the manufacturing god of mass production. He was defending one of our competitors, who had quoted a lead time that was significantly longer than Carrio’s. “As a company grows, lead times grow,” he said. “That’s just the way it is. Everybody knows that.”

The implication was that my competitor’s services were in demand and therefore, more desirable and that accepting long lead times was part of the price of working with what must be a successful company…like a badge of honor. Of course, the converse was also implied: Because Carrio Cabling’s cycle times are so short, our business must be unstable and unsuccessful. Clearly, in this goofball’s world, we didn’t have enough business; if we did, we wouldn’t be able to deliver quickly.

This upside-down view of lengthy lead times is a symptom of the extent to which the mass production view of the world is embedded in our brains. In the mass production mentality, companies “batch” steps of the manufacturing process; obviously then, as orders stack up, it’s going to take longer to get product through the phases of the system. You don’t have to look far to see the effects of this nutty approach. Insurance claims, refund checks, requests for public documents. How long could it possibly take to process a refund check, for example? An hour? Two hours? But how long does it take to get your check? More like 6-8 weeks, if you’re lucky, right?

In fact, if the lead times of one of my suppliers grow as its business grows, I turn up the CSM™ – the patented Carrio Scrutineering Meter. First of all, company growth has zero bearing on the ability to move in the marketplace. There’s nothing glamorous, or better, or smarter about working with a growing company. In addition, creeping lead times are nearly always a signal that the company’s processes have been poor from the get-go. Growing cycle times have simply amplified weaknesses that have been there all along…weaknesses that are likely the result of some version of batching the steps of production.

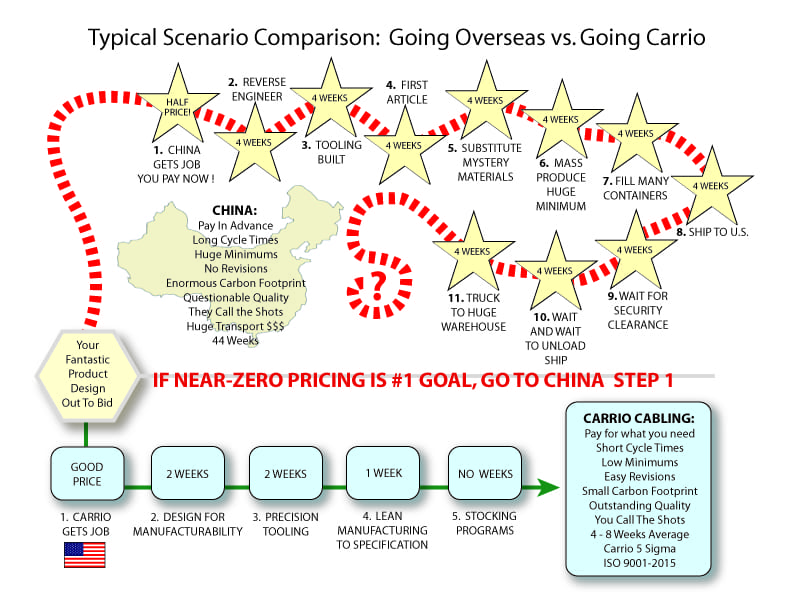

Carrio’s lead times have always been short: Raw material lead time plus a one-day build. Short lead times have many advantages, the most obvious of which is that your customers will be infinitely happier. But “what’s in it for me,” you might ask, in addition to simply meeting customers’ never-ending desire for product now, now, now? Why should you shorten your lead times? Fact is, there’s a lot in it for you, if you have the courage to do it.

Numero uno, quick turn-around times expose weaknesses – supply chain problems, poor or ineffective customer service, waste and inefficiency in handling, and manufacturing process weaknesses that equate to higher defects.

Numero deuce, speedy cycle times make your company and your customers more responsive to a changing marketplace. The latest product improvement or new product can be implemented to meet the very latest demands and needs now, when the marketplace is hot, not sometime out in the future when the window has closed.

Numero tres, the ability to deliver product nearly as quickly as the raw materials are in hand makes customers very happy. Happy customers stick around; unhappy customers go away.

Carrio Cabling’s one-day build cycle goes hand in hand with the lot-size-of-one process we have used for more than 15 years. It isn’t mystical or difficult. But it does require upending the long-standing fascination people seem to have with mass production and continually educating about the unbelievable value to everyone of one at a time.